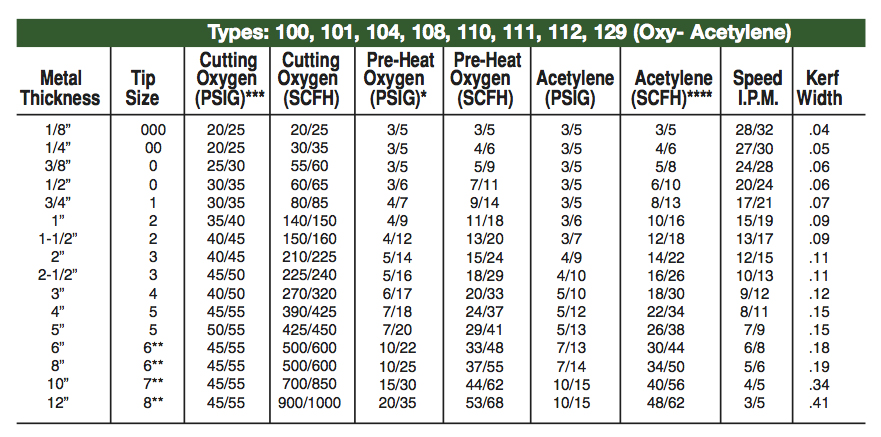

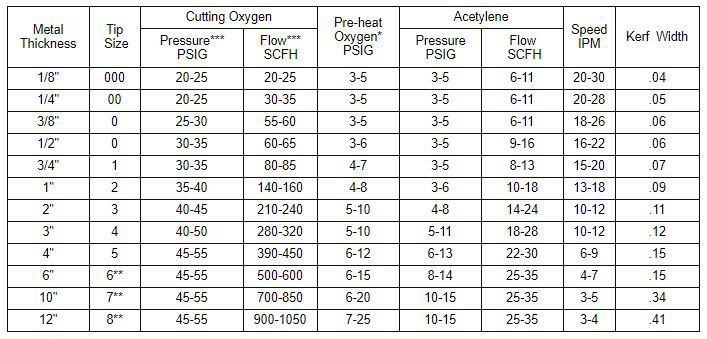

Oxy Acetylene Torch Settings Chart

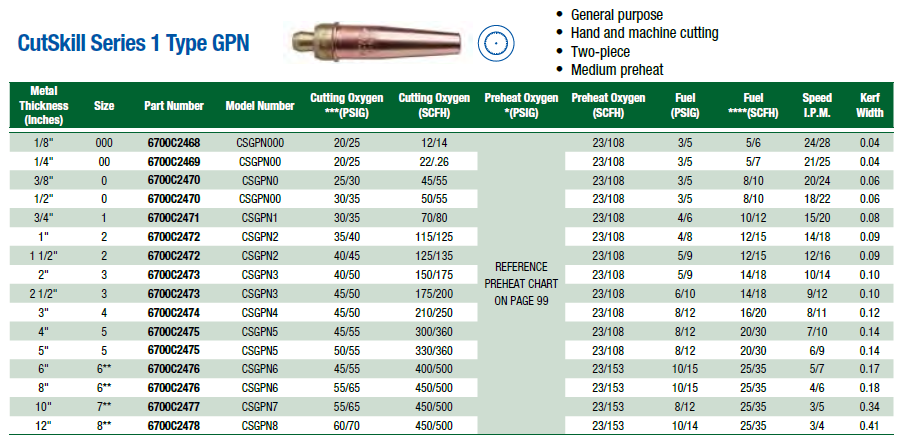

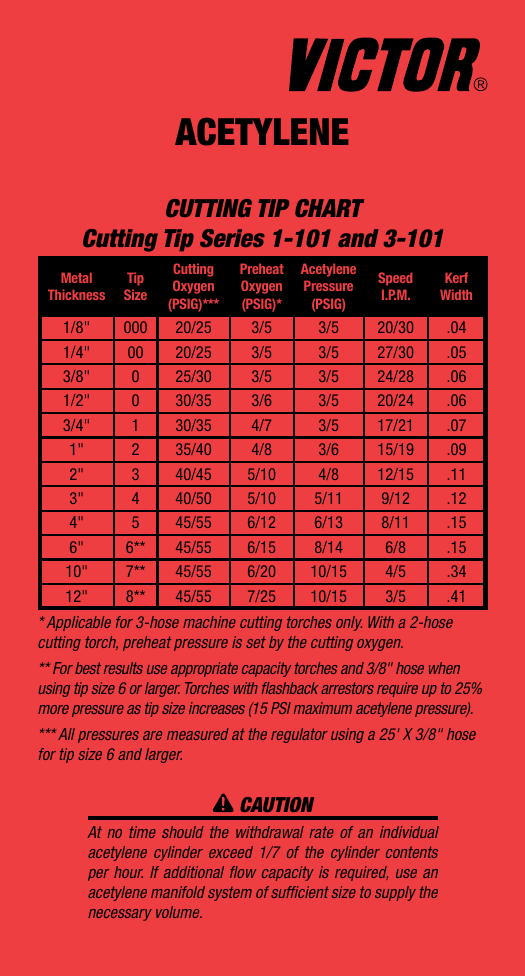

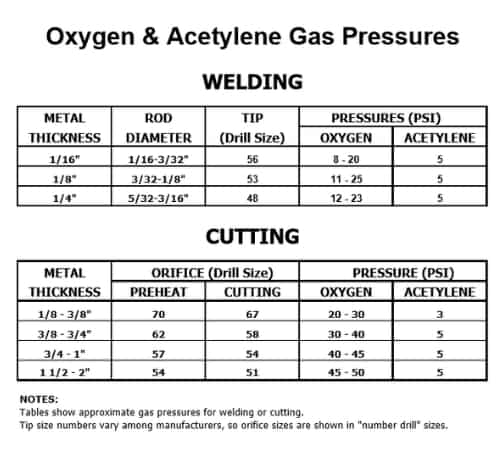

Oxy Acetylene Torch Settings Chart. The manufacturer of your torch has charts for type of tip and their proper pressures. Recommended oxygen and fuel gas pressures are at the torch with gas flowing.

20 rows all torches with flashbacks arrester need more pressure, 25% more per tip increase. What flux do you use for brazing? *size 12, 20 and mfa heating nozzles must be used with hd 310c torch handle and 3/8 (9.5 mm) hose.

Its submitted by presidency in the best field. Most of the welders face the oxidizing problem while they are trying to use a regulator.

Oxy acetylene welding set up and pressure settings chart : Slowly add oxygen—flame will sharpen and elongate.

16 problem solving victor rosebud chart, victor rosebud chart skinology, oxy fuel welding and cutting wikipedia, 69 explanatory oxy acetylene torch tip size chart, pin on metalworking Recommended oxygen and fuel gas pressures are at the torch with gas flowing.

This regulator becomes a centerpiece of your whole welding session. Equipment oxy/acetylene equipment is portable and easy to.

*size 12, 20 and mfa heating nozzles must be used with hd 310c torch handle and 3/8 (9.5 mm) hose. ** for best results use appropriate capacity torches and 3/8 hose when using tip size 6 or larger.

Contact them or go online for their charts. *size 12, 20 and mfa heating nozzles must be used with hd 310c torch handle and 3/8 (9.5 mm) hose.

*size 12, 20 and mfa heating nozzles must be used with hd 310c torch handle and 3/8 (9.5 mm) hose. The instructor turns the adjusting screw for the oxygen tank out.

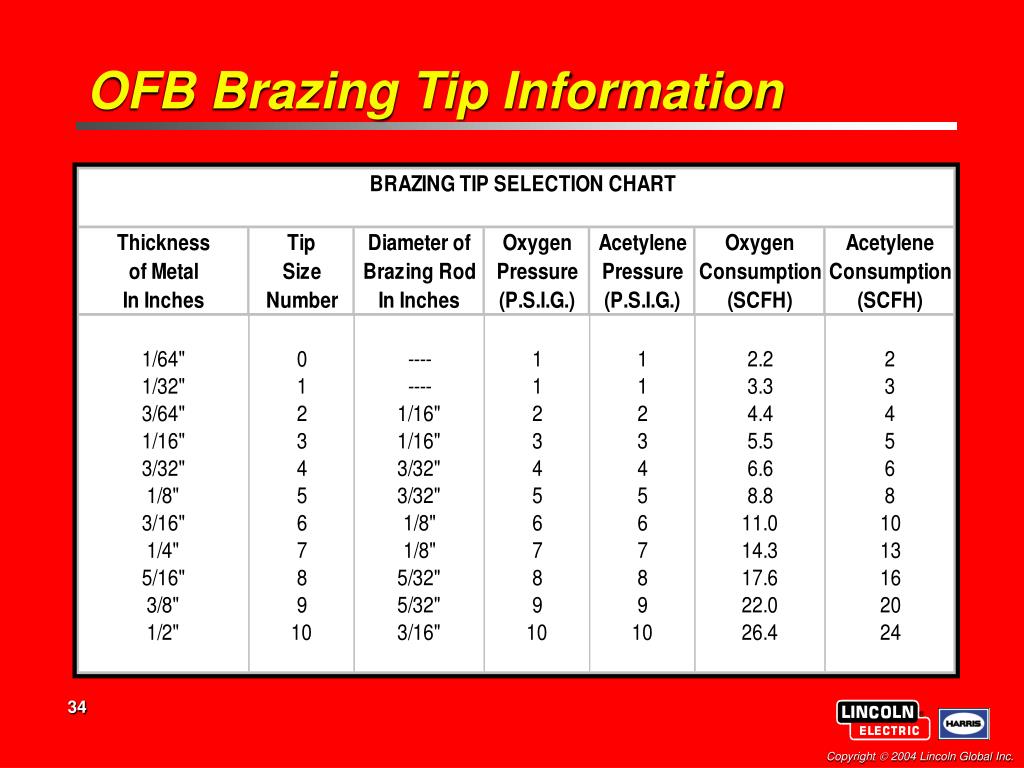

What flux do you use for brazing? Welding brazing heating oxyacetylene welding equipment welding hoses miller smith 23 5004a quickbraze oxy welding hoses.

What flux do you use for brazing? Stand away from front of regulator.

Open regulator oxygen and acetylene, set until the pressure matching with what do you want or for acetylene 5 to 7 psi and oxygen 7 to 10 psi. Oxy acetylene cutting pressure settings chart written by kupis on november 22, 2020 in chart petrogen torch module lesson plans i learn for life acetylene vs alternate fuel the oxy acetylene cutting torch settings c welding hoses

The third open valve in the torch, first acetylene after that you can open oxygen valve. ** for best results use appropriate capacity torches and 3/8 hose when using tip size 6 or larger.

Oxy acetylene welding ofw fundamentals pressure settings chart set up and kit. If there is too much acetylene, flame breaks away from the tip.

Oxy acetylene welding ofw fundamentals pressure settings chart set up and kit. Depress cutting lever and adjust pressure if necessary.

Oxy acetylene welding ofw fundamentals pressure settings chart set up and kit. Bottle equipment setup tips and guide:

The third open valve in the torch, first acetylene after that you can open oxygen valve. 20 rows all torches with flashbacks arrester need more pressure, 25% more per tip increase.

Bottle equipment setup tips and guide: If there is too much acetylene, flame breaks away from the tip.

20 rows all torches with flashbacks arrester need more pressure, 25% more per tip increase. Oxy acetylene welding set up and pressure settings chart :

The instructor turns the valves on cutting torch off. Adjust acetylene to form feather shaped flame.

Torches with flashback arrestors require up to 25% more pressure as tip size increases (15 psi maximum acetylene pressure). Open regulator oxygen and acetylene, set until the pressure matching with what do you want or for acetylene 5 to 7 psi and oxygen 7 to 10 psi.

Stand away from front of regulator. Adjust regulator p/a screws to tip pressure settings.

Separately And Slowly Open The Oxygen And Acetylene Cylinder Valves.If there is too much acetylene, flame breaks away from the tip. *size 12, 20 and mfa heating nozzles must be used with hd 310c torch handle and 3/8 (9.5 mm) hose. Open/close torch valves separately and fine tune pressure settings on regulators.

Torches With Flashback Arrestors Require Up To 25% More Pressure As Tip Size Increases (15 Psi Maximum Acetylene Pressure).** for best results use appropriate capacity torches and 3/8 hose when using tip size 6 or larger. Never exceed 15 pounds per square inch (psi) when using acetylene. Oxy acetylene cutting torch pressure settings regulator · oxy acetylene cutting pressure settings chart written by kupis on november 22, 2020 in chart figure 4 16 m gas cutting c 32 cutting torch oki bering oxy acetylene welding and cuttng boc lines for welding and cutting oxy fuel torch tip nozzle design and

In Order To Comfortably And Safely See The Flame When Welding Or Cutting, Welding Goggles Must Be Worn.Adjust acetylene to form feather shaped flame. Torches with flashback arrestors require up to 25% more pressure as tip size increases (15 psi maximum acetylene pressure). Adjust regulator p/a screws to tip pressure settings.

Most Of The Welders Face The Oxidizing Problem While They Are Trying To Use A Regulator.Make sure torch valves are closed. The manufacturer of your torch has charts for type of tip and their proper pressures. Open regulator oxygen and acetylene, set until the pressure matching with what do you want or for acetylene 5 to 7 psi and oxygen 7 to 10 psi.

** To Provide Required Flow, Use 3/8 I.d.Think of the two numbers, 10 and 5. Make sure torch valves are closed! The above image is an oxy acetylene cutting torch setup chart (except this image shows the setup with an oxy acetylene welding torch).

Belum ada Komentar untuk "Oxy Acetylene Torch Settings Chart"

Posting Komentar